Are you curious about how a simple paper bag is made? Many people don’t realize the intricate process behind creating something as everyday as a paper bag. The journey of a paper bag, from raw materials to the final product delivered to your doorstep, involves multiple steps, each crucial in ensuring the quality and sustainability of the final product.

In this blog post, I will take you through the entire process of paper bag production, from sourcing materials to manufacturing, quality control, and logistics. Understanding this journey will not only give you insight into our business at HMZ Technology but also help you appreciate the craftsmanship and effort that goes into every paper bag.

Ready to dive into the fascinating world of paper bag production?

Sourcing the Right Materials

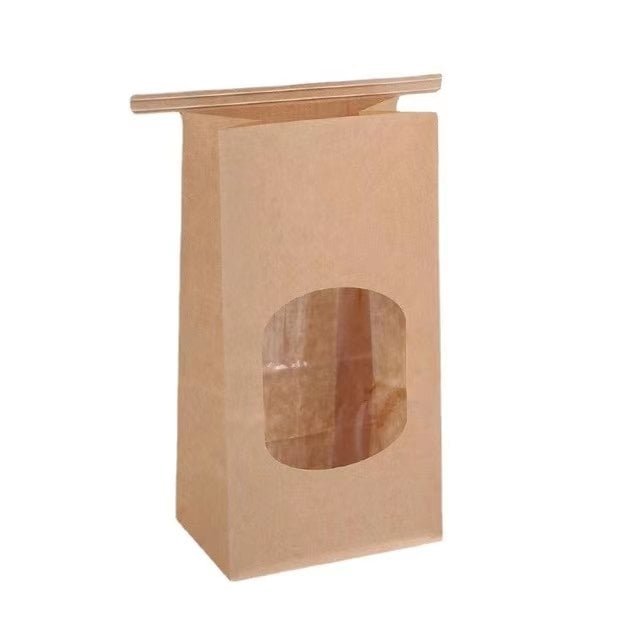

The first step in the production of paper bags is sourcing the right materials. At HMZ Technology, we prioritize sustainability and quality. We source high-quality kraft paper from reputable suppliers. Kraft paper is preferred due to its strength, durability, and eco-friendly nature. Our suppliers are carefully selected to ensure they adhere to environmental and quality standards.

The raw materials we use are crucial to the final product’s quality. By choosing the best materials, we ensure our paper bags are not only sturdy but also biodegradable, contributing to environmental conservation.

The Manufacturing Process

Once the materials are sourced, the manufacturing process begins. Our factory in China is equipped with eight production lines and employs over 50 skilled workers. The process starts with the paper being fed into machines that cut and fold it into the desired shapes and sizes.

Next, the bags are assembled. This involves gluing the edges and attaching handles, if required. The precision in this step is crucial to ensure the bags are strong and can carry the intended weight. We use state-of-the-art machinery to maintain consistency and efficiency in production.

Custom Printing and Branding

One of our competitive advantages at HMZ Technology is the ability to offer custom printing on our paper bags. Customization is important for our clients who want to promote their brand. We use advanced printing technology to ensure high-quality, vibrant prints that are durable and attractive.

Our printing process allows for a wide range of colors and designs, providing flexibility for our clients to create unique, branded packaging. This step not only adds value to the paper bags but also helps businesses in their marketing efforts.

Quality Control Measures

Quality control is a critical part of our production process. Each batch of paper bags undergoes rigorous testing to ensure they meet our high standards. This includes testing the strength and durability of the bags, as well as checking the quality of the printing.

We have a dedicated quality control team that inspects every stage of production. This meticulous attention to detail ensures that our clients receive only the best products, minimizing the risk of defects and ensuring customer satisfaction.

Logistics and Delivery

After production and quality control, the next step is logistics. Efficient logistics are essential to ensure that our paper bags reach our clients on time and in perfect condition. We have a robust logistics system in place, including partnerships with reliable shipping companies.

Our logistics team coordinates the packing and shipping of the paper bags, ensuring they are properly packed to prevent damage during transit. We export our products to various countries, including Canada, the United States, and several European markets.

Related Questions:

How Custom Printed Paper Bags Can Enhance Your Brand Image?

Custom printed paper bags are a powerful tool for enhancing your brand image. They serve as a mobile advertisement, spreading your brand’s message wherever they go. With high-quality printing and unique designs, your brand can stand out in the marketplace and create a lasting impression on your customers.

A Comprehensive Guide to Kraft Paper Tableware?

Kraft paper tableware is not only eco-friendly but also versatile and durable. In this comprehensive guide, we will explore the benefits of using kraft paper tableware, the different types available, and how they can be customized to fit your brand’s needs. This guide will help you make an informed decision when choosing kraft paper tableware for your business.

Conclusion

The journey of a paper bag from production to delivery is a complex process that involves careful planning and execution. At HMZ Technology, we pride ourselves on our attention to detail and commitment to quality at every step. By understanding this process, you can appreciate the value and effort that goes into producing high-quality paper bags.

Interested in learning more about our products or services? Contact us today to discuss how we can meet your food packaging needs.